Metal construction and welding

- ENGINEERING

We provide design study for metallic and mixed structures, as well as their execution via our engineering office. It puts in place calculations and design tools from requirement sheet analysis to plans and execution documents.

Il est constitué d’ingénieurs et de techniciens disposant de compétences et connaissances élargies dans les domaines de la conception d’équipements (process, mécanique), des procédés de fabrication (usinage, soudure, traitement thermique, traitement de surface) et des contrôles (CND, test d’épreuve, etc) complétés par une grande maîtrise des codes de construction, normes et réglementations.

We accompany you in the following activities:

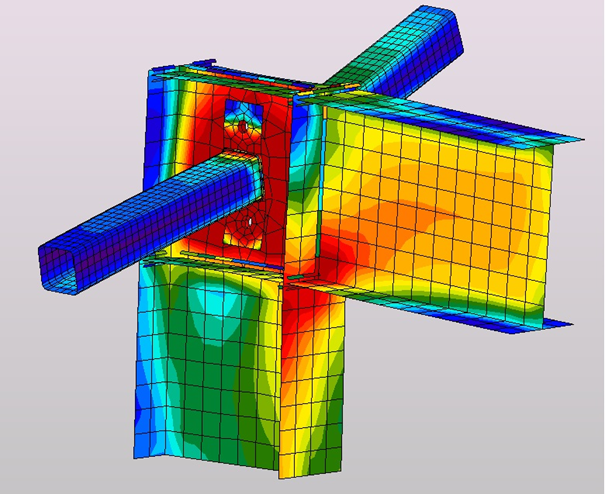

Design and pre-study (pre-sizing, 3D modelling, etc.)

Technical assistance

EXE file (calculation note, load descent, general and detailed drawings, manufacturing file, etc.)

Site supervision / execution

- Manufacturing (Boiler making-Piping-Structure)

Relying on the skills of our design office, we use our expertise to build or repair your equipment and structures in strict compliance with relevant construction codes and standards.

We repair, manufacture and install various structures and boiler-made equipment in carbon steel as well as in noble metals (austenitic stainless steel, duplex, cupronickel, etc.)

Thanks to our internal organisation, we guarantee our products’ quality and respect of deadlines. We operate on the following products :

Steelwork

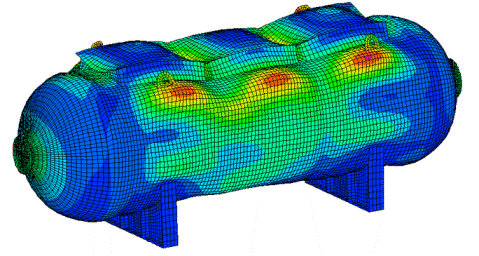

Pressure vessels (Vats, tanks, piping, etc.)

Lifting devices (jib, monorail, etc...) and Basket (according to DNV standards)

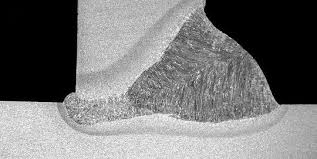

- Welding expertise and advice

We offer to assist you in solving problems related to materials, welding and related techniques (cutting, heat treatment, etc…).

Our added value lies on our experience and know-how in assembling materials, combined with affordable techniques to meet your technical and economic constraints.

We offer complete expert solutions in three main areas :

Assembly Expertise

Welding Materials, Welding Consumables Selection, Welding Codes & Standards, Welding Procedures, Drafting & Development (DMOS – pWPS), Welding Recharges, etc…

Improvement of productivity and competitiveness

Customised assistance including an analysis phase of your needs through the diagnosis of your production tool and environment/industrial context, leading to the definition of an action plan and a roadmap to help your company integrate welding/recharging technologies in order to optimise processes and productivity with the aim of improving competitiveness.